Electrical enclosures are crucial for protecting electrical components and wiring from environmental factors and physical damage. These enclosures come in various materials, each offering distinct benefits. Stainless steel is a top choice for many applications due to its durability and resistance to corrosion. It is particularly valuable in settings where the environment may be harsh, such as industrial sites or coastal areas.

Stainless steel electrical enclosures provide a robust barrier against moisture, dust, and mechanical impacts. They help ensure that electrical systems remain operational and safe from potential hazards. Understanding the advantages of stainless steel can help you make an informed decision when selecting an enclosure for your specific needs.

What is Stainless Steel?

Definition and Composition

Stainless steel is a type of steel known for its resistance to rust and corrosion. It is composed of iron, carbon, and a minimum of 10.5% chromium. The chromium forms a protective layer of chromium oxide on the surface of the steel, which helps prevent corrosion. Other elements like nickel and molybdenum can also be added to enhance specific properties.

The stainless steel used in electrical enclosures is typically of high quality to ensure it meets stringent performance and safety standards. This material’s combination of strength, resistance to corrosion, and aesthetic appeal makes it an excellent choice for various industrial and commercial applications.

Why It’s a Popular Choice for Electrical Enclosures

Stainless steel’s popularity for electrical enclosures stems from its superior properties compared to other materials. It provides excellent resistance to both chemical and environmental damage, making it suitable for demanding applications. Its ability to withstand extreme temperatures and maintain structural integrity under stress further contributes to its widespread use. Stainless steel also has a clean, professional appearance that complements modern infrastructure.

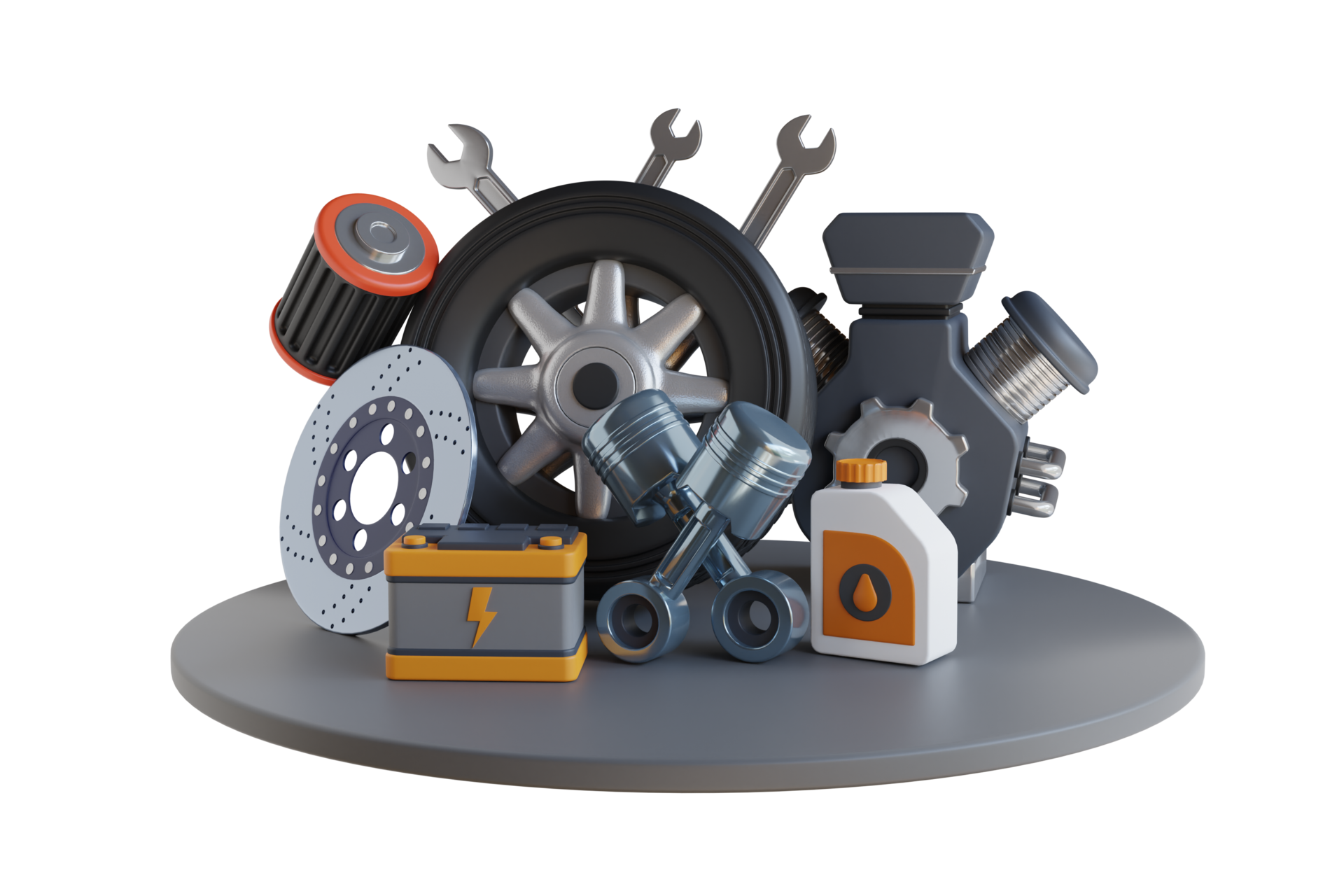

Key Advantages of Stainless Steel Electrical Enclosures

Durability and Strength

Stainless steel electrical enclosures are renowned for their durability and strength. They can withstand significant physical impact, making them ideal for environments where equipment might be subject to heavy use or rough handling. The material’s inherent toughness ensures that the enclosure will not easily dent or deform, preserving the integrity of the enclosed electrical components.

In industrial settings, where machinery and equipment are often subjected to high levels of wear and tear, stainless steel enclosures offer a reliable solution. Their strength ensures that the electrical systems remain protected, reducing the risk of damage and minimizing maintenance needs. This durability translates into long-term cost savings and improved safety.

Corrosion Resistance

One of the most significant advantages of stainless steel is its corrosion resistance. The chromium in stainless steel forms a passive layer that prevents rust and corrosion from developing, even in moist or corrosive environments. This is particularly important in outdoor applications or in industries where exposure to chemicals or saltwater is common.

For instance, in coastal areas where salt spray can accelerate corrosion, stainless steel enclosures provide a durable and long-lasting solution. Their ability to resist corrosion helps maintain the integrity of the electrical components inside, ensuring reliable operation and reducing the likelihood of failures or malfunctions.

Hygiene and Cleanliness

In industries like food processing or healthcare, maintaining a high standard of hygiene is crucial. Stainless steel enclosures are well-suited to these environments due to their smooth, non-porous surfaces, which make them easy to clean and sanitize. The material does not harbor bacteria or contaminants, contributing to a cleaner and more hygienic workspace.

The ease of cleaning stainless steel enclosures also extends to routine maintenance. Their resistance to stains and grime means that they can be wiped down quickly without the need for harsh chemicals. This not only simplifies upkeep but also ensures that the enclosures remain in optimal condition over time.

Common Applications of Stainless Steel Electrical Enclosures

Industrial Use

In industrial settings, stainless steel electrical enclosures are used to protect equipment in harsh environments. These enclosures safeguard electrical systems from dust, moisture, and temperature extremes, ensuring reliable operation in manufacturing plants, chemical processing facilities, and other industrial environments. Their durability and resistance to environmental factors make them ideal for protecting sensitive electrical components and control systems.

Stainless steel enclosures are also used in areas with high exposure to mechanical stress or vibration, where other materials might fail. The robustness of stainless steel helps maintain the integrity of electrical systems, reducing downtime and maintenance costs in industrial operations.

Commercial Use

In commercial settings, Stainless Steel Electrical Enclosure are often used in office buildings, shopping centers, and other public spaces. They provide a clean and professional appearance while offering the necessary protection for electrical components. These enclosures are often used to house electrical panels, circuit breakers, and other essential systems.

The corrosion resistance of stainless steel is particularly beneficial in commercial environments where cleaning and maintenance are frequent. Additionally, the material’s aesthetic appeal helps maintain a modern and polished look, contributing to the overall ambiance of commercial spaces.

Residential Use

Stainless steel electrical enclosures are also suitable for residential applications, especially in outdoor or high-humidity areas. For example, they can be used for housing outdoor electrical connections, garden lighting systems, or home security equipment. The resistance to weather and environmental factors ensures that the electrical components remain protected and functional.

In residential settings, stainless steel enclosures offer both durability and style. Their sleek appearance fits well with contemporary home designs, and their ability to resist environmental damage provides peace of mind for homeowners concerned about long-term performance.

Choosing the Right Stainless Steel Electrical Enclosure

Size and Capacity

Selecting the correct size and capacity for a stainless steel electrical enclosure is crucial for ensuring that it meets your needs. The enclosure must be large enough to accommodate all the electrical components while providing sufficient space for ventilation and maintenance access.

To determine the right size, consider the dimensions of the equipment that will be housed inside, as well as any additional space required for wiring and connections. Proper sizing helps prevent overcrowding, which can lead to overheating or difficulties in accessing components for maintenance.

Protection Ratings

Protection ratings, such as the IP (Ingress Protection) rating, indicate the level of protection an enclosure provides against dust and water ingress. For stainless steel electrical enclosures, understanding these ratings is essential to ensure that the enclosure is suitable for your specific environment.

The IP rating consists of two numbers: the first indicates protection against solid objects (like dust), and the second indicates protection against liquids (like water). Choose an enclosure with a rating that matches the environmental conditions it will be exposed to, such as high humidity or potential exposure to water.

Customization Options

Many stainless steel electrical enclosures can be customized to meet specific requirements. Customization options may include additional features such as locks, ventilation panels, or specialized mounting arrangements.

When selecting an enclosure, consider any unique needs your application may have. For example, if extra security is required, choose an enclosure with robust locking mechanisms. For applications in high-temperature environments, look for options with enhanced ventilation to prevent overheating.

Installation and Maintenance Tips

Proper Installation Practices

Installing stainless steel electrical enclosures correctly is vital for their performance and longevity. Ensure that the enclosure is mounted securely and that all seals and gaskets are properly fitted to prevent ingress of dust or moisture. Follow the manufacturer’s installation guidelines to achieve the best results.

Proper grounding is also important to prevent electrical hazards. Ensure that the enclosure is correctly grounded according to local electrical codes and standards. This helps protect both the enclosure and the equipment inside from electrical faults.

Regular Maintenance

Regular maintenance of stainless steel electrical enclosures is essential for ensuring their continued performance and longevity. Inspect the enclosure periodically for signs of wear or damage, and clean it as needed to remove dirt, dust, or debris.

For enclosures exposed to harsh environments, such as coastal areas or industrial sites, more frequent inspections may be necessary. Address any issues promptly to prevent potential damage or failure. Regular maintenance helps keep the enclosure in good condition and ensures reliable protection for your electrical systems.

Conclusion

Stainless steel electrical enclosures offer numerous benefits, including durability, corrosion resistance, and ease of maintenance. They are suitable for a wide range of applications, from industrial to residential settings, providing robust protection for electrical components in various environments.